ʻO ke kinikini TZM ka mea maikaʻi loa i kēia manawa no ke kinikini molybdenum mehana kiʻekiʻe. He kinikini paʻa ia i hoʻopaʻa ʻia a hoʻoikaika ʻia e nā ʻāpana, ʻoi aku ka paʻakikī o TZM ma mua o ka metala molybdenum maʻemaʻe, a ʻoi aku ka mahana recrystallization kiʻekiʻe a me ke kūpaʻa kolo maikaʻi, ʻo ka mahana recrystallization ma kahi o 1400 ° C, ʻoi aku ka kiʻekiʻe no ka molybdenum, hiki iā ia ke hāʻawi i ka solderability maikaʻi.

He molybdenum alloy i hoʻonui ʻia i nā ʻāpana ʻo MHC me ka hafnium a me ke kalapona. Ma muli o ka hoʻolaha like ʻana o nā carbides ultrafine, hōʻike mau ka mea i nā pono o ke kūpaʻa wela maikaʻi loa a me ke kūpaʻa kolo i ka mahana o 1550 °C, a ʻo ka mahana hana kiʻekiʻe i ʻōlelo ʻia he 150 °C ke kiʻekiʻe ma mua o TZM. No ka laʻana i nā make extrusion, hiki iā ia ke kū i nā ukana wela a me nā mīkini koʻikoʻi, no laila ua ʻōlelo ʻia nā mea MHC no nā noi hana metala.

ʻO ka molybdenum-zirconium alloy, i hoʻohui ʻia me kahi liʻiliʻi o ka zirconia (ZrO2) i loko o ka molybdenum maʻemaʻe, hiki ke hoʻoikaika i ke kūpaʻa ʻana i ka corrosion a me ke kūpaʻa kolo o ka molybdenum.

ʻO ka hoʻohui ʻana i nā mea honua laha ʻaʻole hiki ke hoʻomaikaʻi wale i ka mahana recrystallization a me ke kūpaʻa kiʻekiʻe o ka molybdenum, akā e hōʻemi nui hoʻi i ka mahana hoʻololi plastic-brittle o ka molybdenum, hoʻonui i ka ductility, a hoʻomaikaʻi i ka brittleness o ka lumi a me ke kūpaʻa kiʻekiʻe o ka sag o ka molybdenum.

Noi

Ma muli o kona ikaika wela kiʻekiʻe maikaʻi loa, ka mahana recrystallization kiʻekiʻe a me ka conductivity thermal maikaʻi, hoʻohana nui ʻia ka TZM alloy i ka aerospace, aviation a me nā ʻoihana ʻē aʻe, e like me ka mea nozzle, ka mea nozzle, ke kino valve gas, ka pipeline paipu gas. Hiki ke hoʻohana ʻia e like me nā ʻāpana anode rotating X-ray, nā ʻōmole make-casting a me nā ʻōmole extrusion, nā mea hoʻomehana a me nā pale wela i nā umu wela kiʻekiʻe.

Hoʻohana nui ʻia nā mea hoʻohuihui MHC i nā noi hana metala:

● Hoʻohana nui ʻia ka uea molybdenum honua laha ʻole e like me ke kaula uila kumu kukui, ka electrode EDM a me ka mea hoʻomehana umu wela kiʻekiʻe.

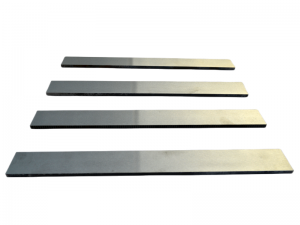

● Hoʻohana ʻia nā papa a me nā pepa molybdenum honua laha ʻole e like me nā wafers no ke kuʻi ʻana i loko o nā thyristors, a me nā pale wela a me nā pepa alakaʻi no nā paipu uila.

● Hiki ke hoʻohana ʻia ka molybdenum alloy honua laha ʻole e like me ke poʻo perforation wela kila kiʻekiʻe, a me nā mea hana aerospace a me ka ʻoihana nukelea, nā pahuhopu pou X-ray, nā make make-casting a me nā make extrusion.

● Hoʻohana ʻia nā huahana ʻano molybdenum honua laha ʻole e like me nā electrodes hoʻoheheʻe aniani, nā electrodes hoʻoheheʻe honua laha ʻole, nā ipu hoʻoheheʻe, nā waʻa sintering wela kiʻekiʻe, nā pale wela radiation wela kiʻekiʻe, nā awa kahe, nā ala alakaʻi, nā pads, a pēlā aku.

● Hiki ke hoʻohana ʻia nā hui molybdenum honua laha ʻole ma ke ʻano he mau mea cathode wela no nā paipu uila mana waena a me ke kiʻekiʻe. Hoʻololi ka mea cathode thermal molybdenum alloy honua laha ʻole i ka cathode tungsten spallation o kēia manawa, nona ka mahana hana kiʻekiʻe, ka haumia radioactive, a me ke kiʻekiʻe o ka brittleness, a hiki ke hoʻemi nui i ka mahana hana o ka paipu a hoʻomaikaʻi i ka hilinaʻi.

Hana nui ʻo Baoji Winners i ka tungsten a me ka molybdenum a me kāna mau mea hoʻohuihui a hiki ke hoʻopilikino ʻia e hoʻokō i nā pono o nā mea kūʻai aku. No ka ʻike hou aku e pili ana i ka huahana, e ʻoluʻolu e kelepona mai iā mākou (Whatsapp: +86 156 1977 8518).

Ka manawa hoʻouna: ʻAukake-02-2022